Safety that Matters. Innovation that Protects.

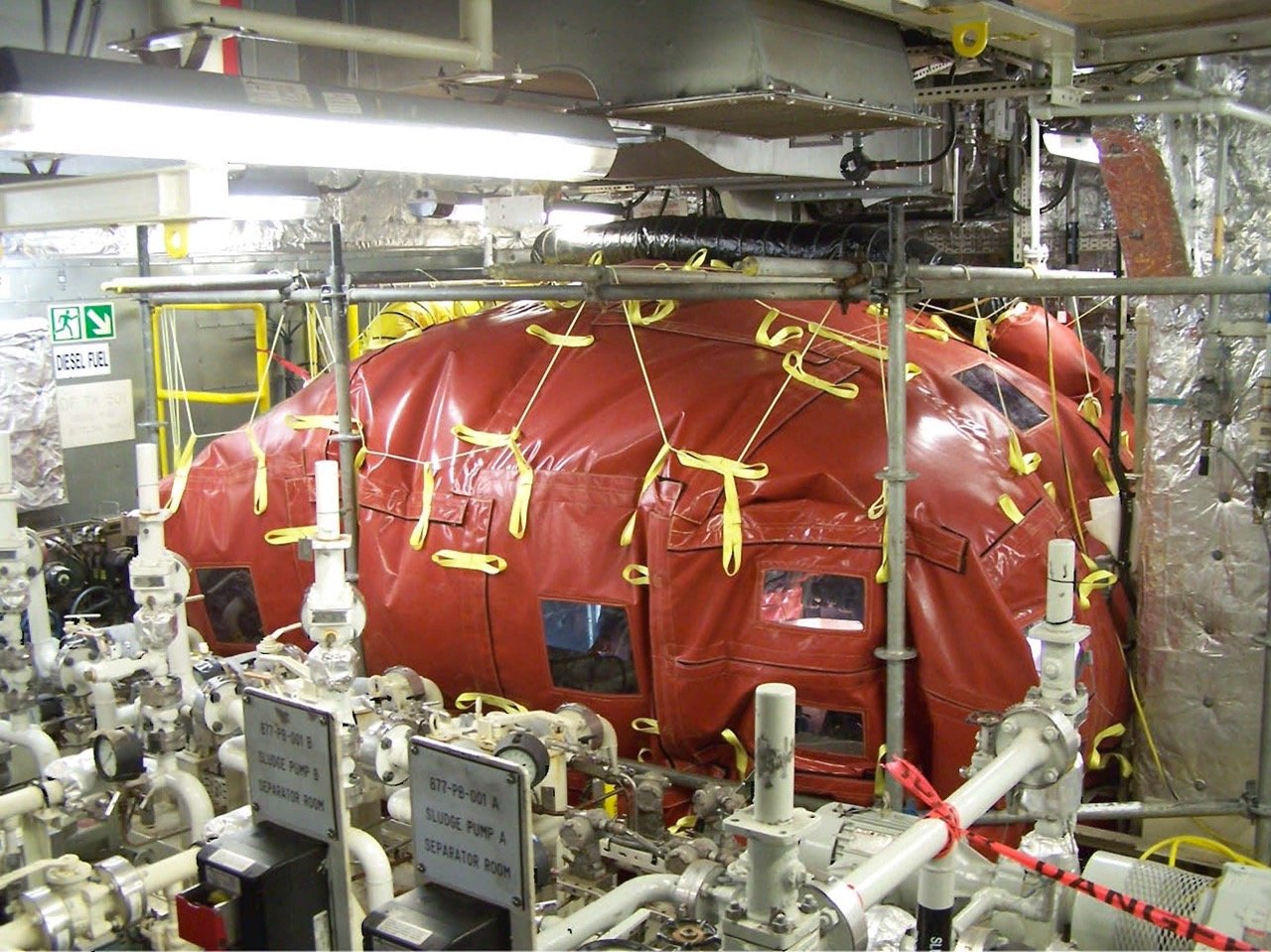

Our Pressurized Welding Enclosures (PWEs) are structures designed/engineered for conducting hot work such as welding, grinding, torching, and cutting in hazardous environments — keeping your team safe and production humming.

We are the crossroad of cutting-edge technology and agile safety.

Our PWE system consists of two main components

Soft-Sided, Modular Paneling that creates a controlled, pressurized environment + prevents the intrusion of flammable gasses

Automatic Shutoff System (ASO) that continuously monitors the enclosure’s internal atmosphere, automatically shutting down ignition sources if unsafe conditions are detected.

How Our PWEs are Used

Flexible Setup — Our PWEs are set up using highly adaptable, modular panels by our team of safety experts, ensuring quick and efficient installation in any environment — even around grating.

Pressurized Environment — The enclosure is carefully pressurized using a ventilation system that maintains a constant, positive pressure within the workspace, preventing the ingress of hazardous gasses.

Continuous Monitoring — Our ASO system continuously monitors the internal atmosphere and automatically addresses any unsafe conditions, ensuring a consistently safe working environment.

Ultimate Safety and Efficiency — With the Safe Arc Technology team and our advanced PWEs, we help you achieve maximum safety and operational efficiency.

Our PWEs at Work

Let’s Talk

Safety solutions that save you time and money.